Exit Academia, Enter STartup Life

One of the many reasons I joined Miller Lab was to get a taste of the PhD life, something I was considering for a next move. After much internal dialogue, I decided it wasn't for me (at least not at this time). I wanted to revisit spinning up a business of my own, something I had done previously with Matterfy (we sold the Melzi microcontroller to drive 3D printers before it was cloned to kingdom come).

Though it was a profitable venture, there was still so much I had to learn about running a business. I discovered that Rice University actually had an accelerator program, OwlSpark, that was entering its third year and open to not just students but staff too! I had spent the past couple of years devoted entirely to developing a DLP 3D printer, I wanted to produce a refined version and sell it. Putting together a rag tag team in a few weeks, I applied, interviewed and was accepted! I informed Miller Lab of my plans and my last day in the lab. Summer came and I dove head first into OwlSpark.

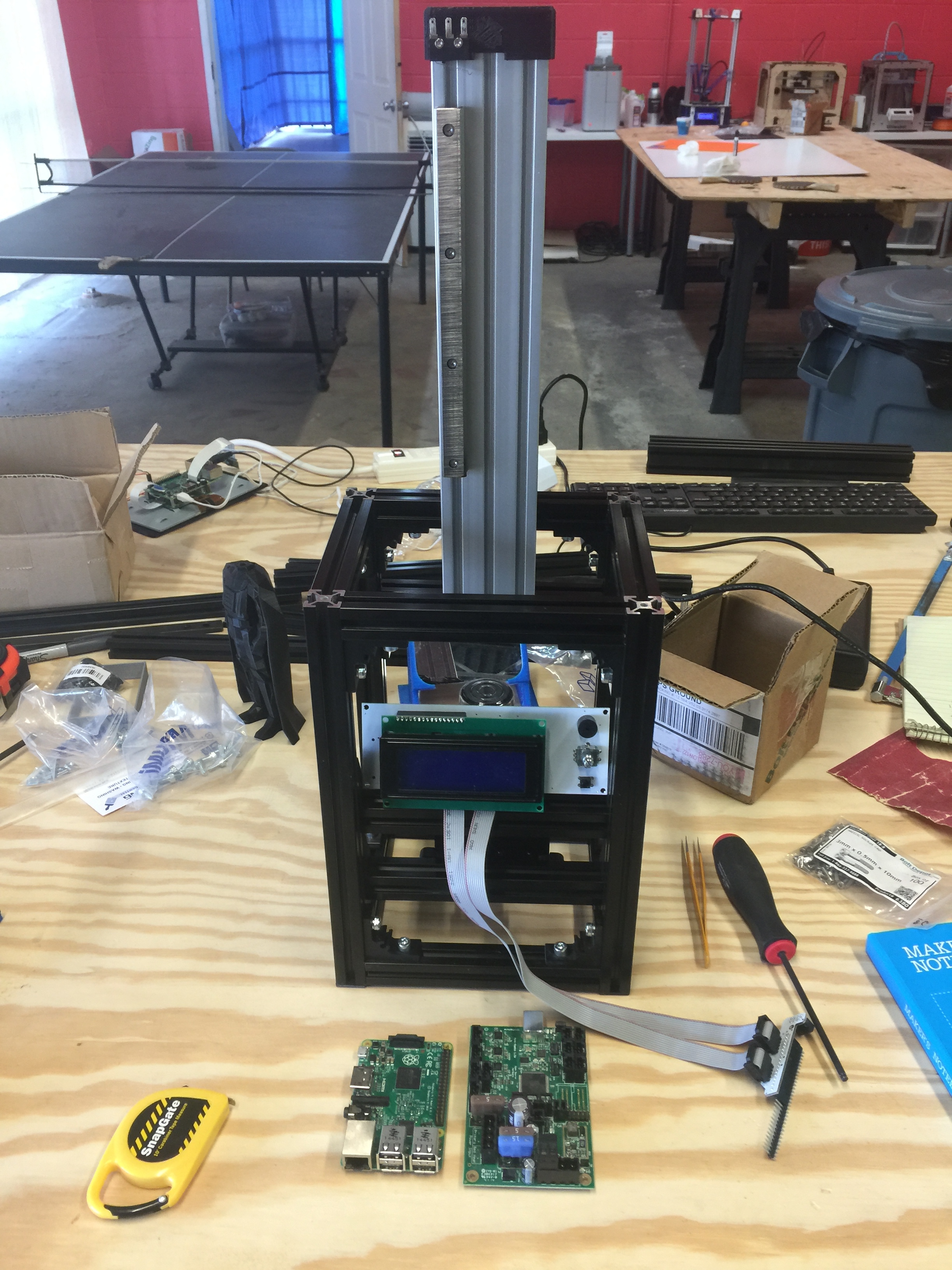

The Flash DLP

The Flash wins a People's Choice award at Kansas City MakerFaire

Yeah, that's the name of our printer...the Flash (you know, cause a whole layer happens in a flash)! Given my roots with the RepRap Project, I wanted to start with a DLP printer that could be built with another 3D printer. So it's not a resin printed resin printer, but it is a FDM/FFF printed resin printer.

Throughout the accelerator program we engaged customer via phone but also in person at tradeshows. We started getting pre-orders and started shipping at the end of the program. We were already profitable by the end of the program!

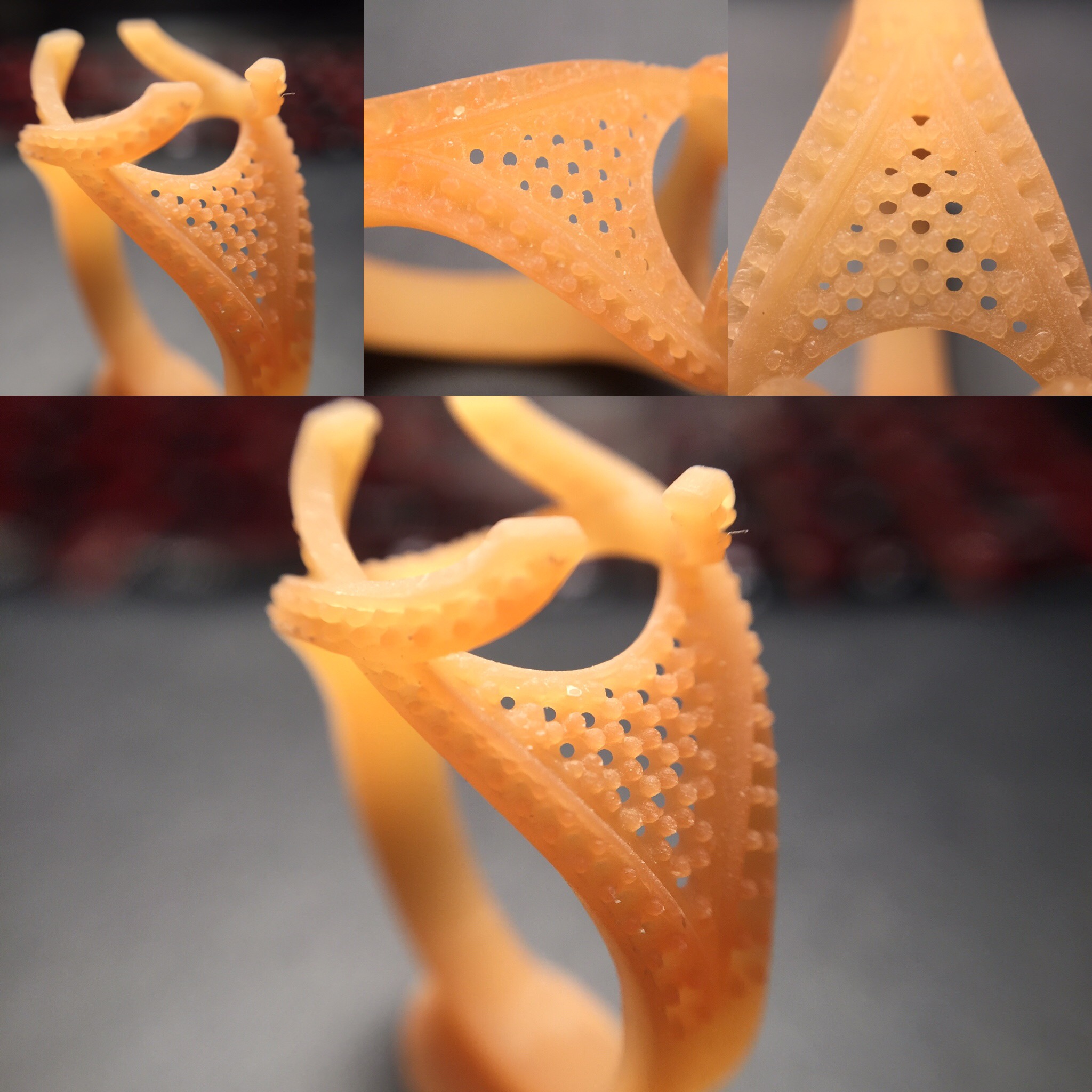

Close up of the gyroid spehere

Bayou Startup Summer 2015

OwlSpark is an accelerator program that spans 12-weeks. During that time we'd explore the many facets to launching a startup following Steve Blank's Lean Startup process. Having made an attempt at launching previously, this was the absolute best opportunity to test my hypotheses and try to figure out whether or not I even had anything to build a business around. Given the high probability of failure for most startups, anything I could do to tip the odds in my favor any bit was a chance worth taking. There is no better way to learn about launching a startup than being in close proximity with a large number of like minded individuals who are trying to do the same.

There is no real value I could put on the experiences here. Not only did I get to put my business model into a pressure cooker, I also established a network in the Houston area that continues to help me to this very day.

Life After OwlSpark

So the program ended and we kept on going (still active today!). We quickly ran into some trouble spots, for starters...3d printing a 3d printer as a means of production (at least given the design we had) is not very economical. It's an absolute great conversation piece, but we had more demand than we could timely produce (typically a good problem to have but not when you don't have an immediate solution).

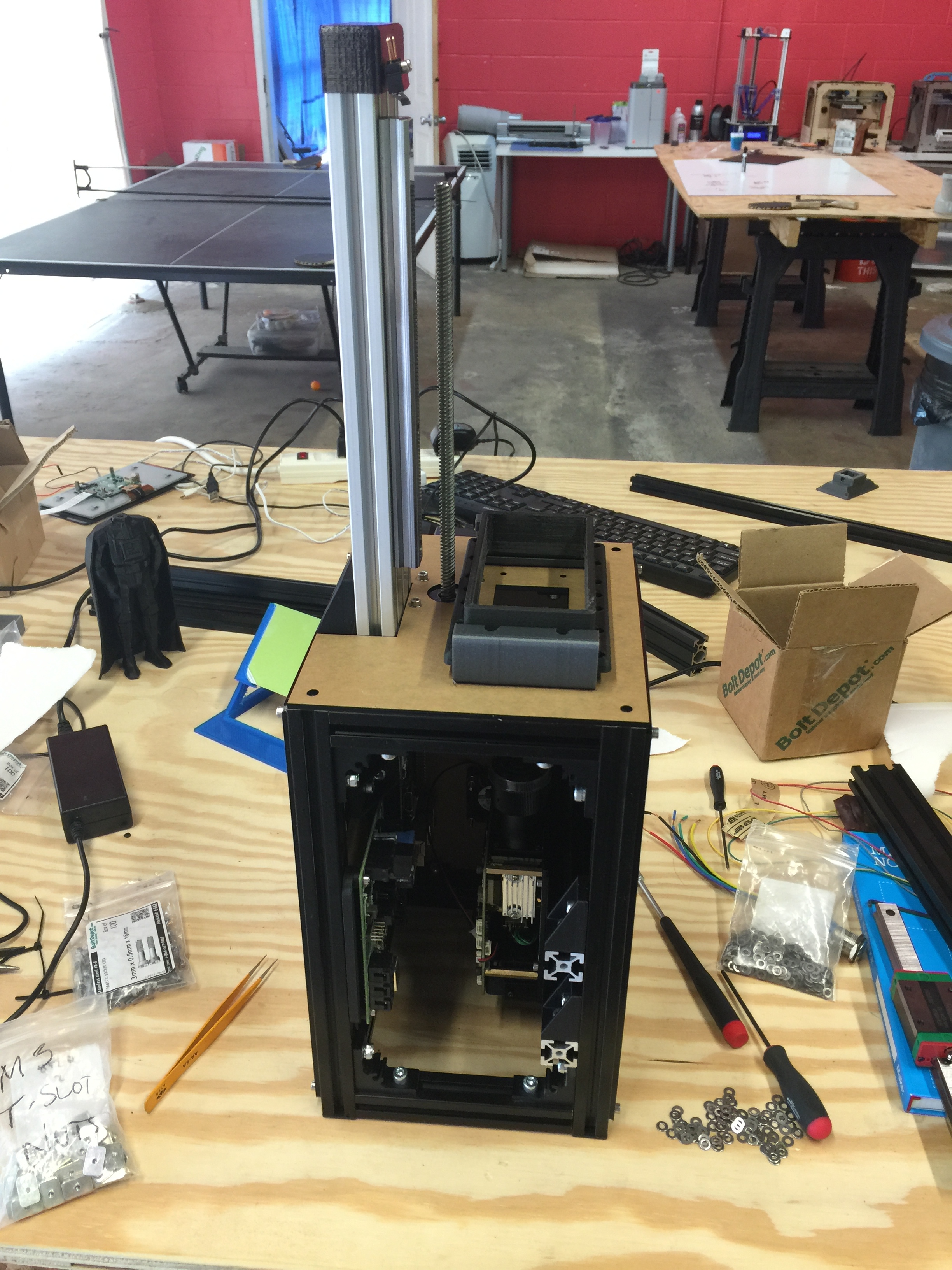

Flash 2.0 render from Fusion360

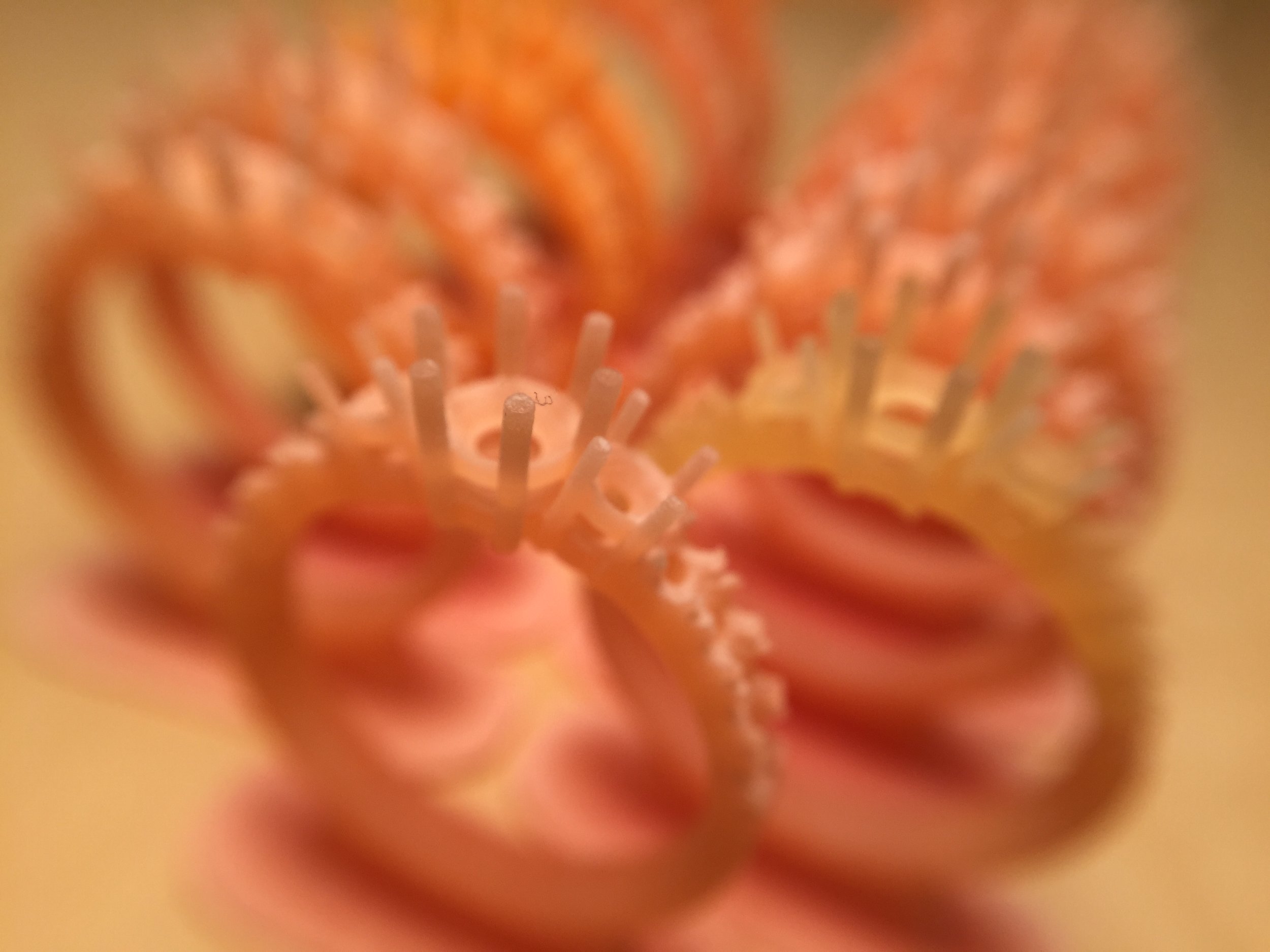

This spurred the next generation design of the Flash, but as we were developing the new printer, we actively spoke with our customers. We found out that they didn't really care about the printer itself, but more so what it created for them. Our main customer base was jewelers. They were using our printers to print in castable resins and going through the investment casting process. With this new information, we stopped developing a printer to sell to customers, but instead built hardware specifically for us to run a service.

We ran an SLA printing service for wax castings and started to expand to include FFF/FDM printing services too. Business is still going good!