Whiteboard sketch for multimaterial DLP (MMDLP) 3D printing concept

Overview

After spending a year or so with the DLP system, I wanted to explore ways to increase the functionality of the system. I wanted to be able to do multicolored parts, but around the same time new resins with different properties were also coming to market. After doing some background research, and seeing a few other examples of a multimaterial configuration of a DLP 3D printer, I had a concept in mind.

Some of the examples I found used a few different approaches to creating a multimaterial system. One used a carousel-like system to move the vats/reservoirs into the printing position. Between the reservoirs of materials, there were "decontamination" areas to limit the cross contamination of materials.

Another approach was to have a single reservoir, fill and drain materials as needed. Though this process allowed for a simpler and smaller footprint, it was highly wasteful in terms of materials. Every time one would drain the reservoir, a follow up rinse would render the material unusable due to contamination of the previous material or the intermediate rinsing solution.

Printer Design & Function

Based on my findings, I took bits and pieces of what I liked from the various approaches. Given the various applications that was going on in the lab I had a few constraints to deal with:

- I didn't want to rebuild an entire new system. So that meant whatever I did had to be adaptable or up-gradable from the DLP systems we currently had around the lab.

- I wanted to keep the footprint as compact as the original system. The driving thought here was to be able to squeeze as many machines into a space as possible.

- I wanted to keep the same workflow. We invested a lot of time hacking through CreationWorkshop (CW) and had built up familiarity with it, not to mention also having a good relationship with it's developer.

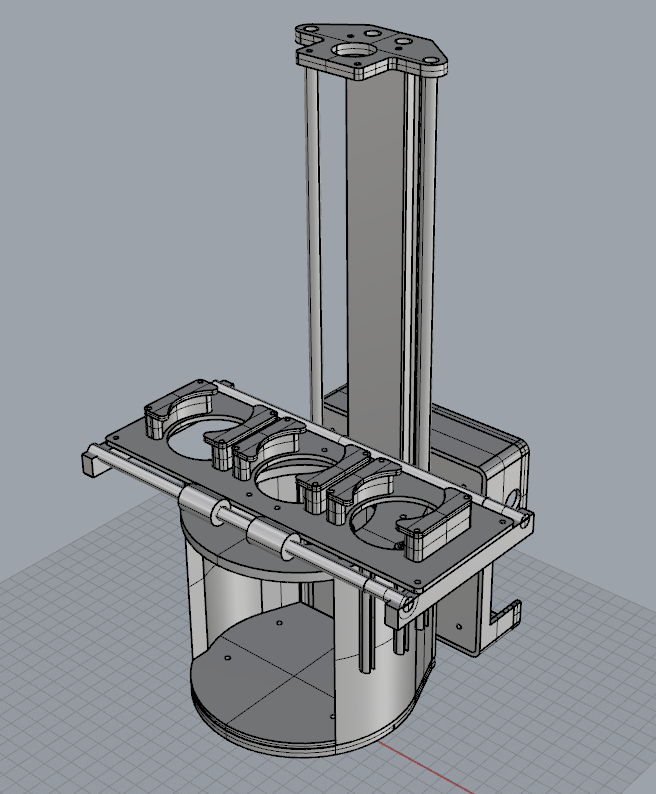

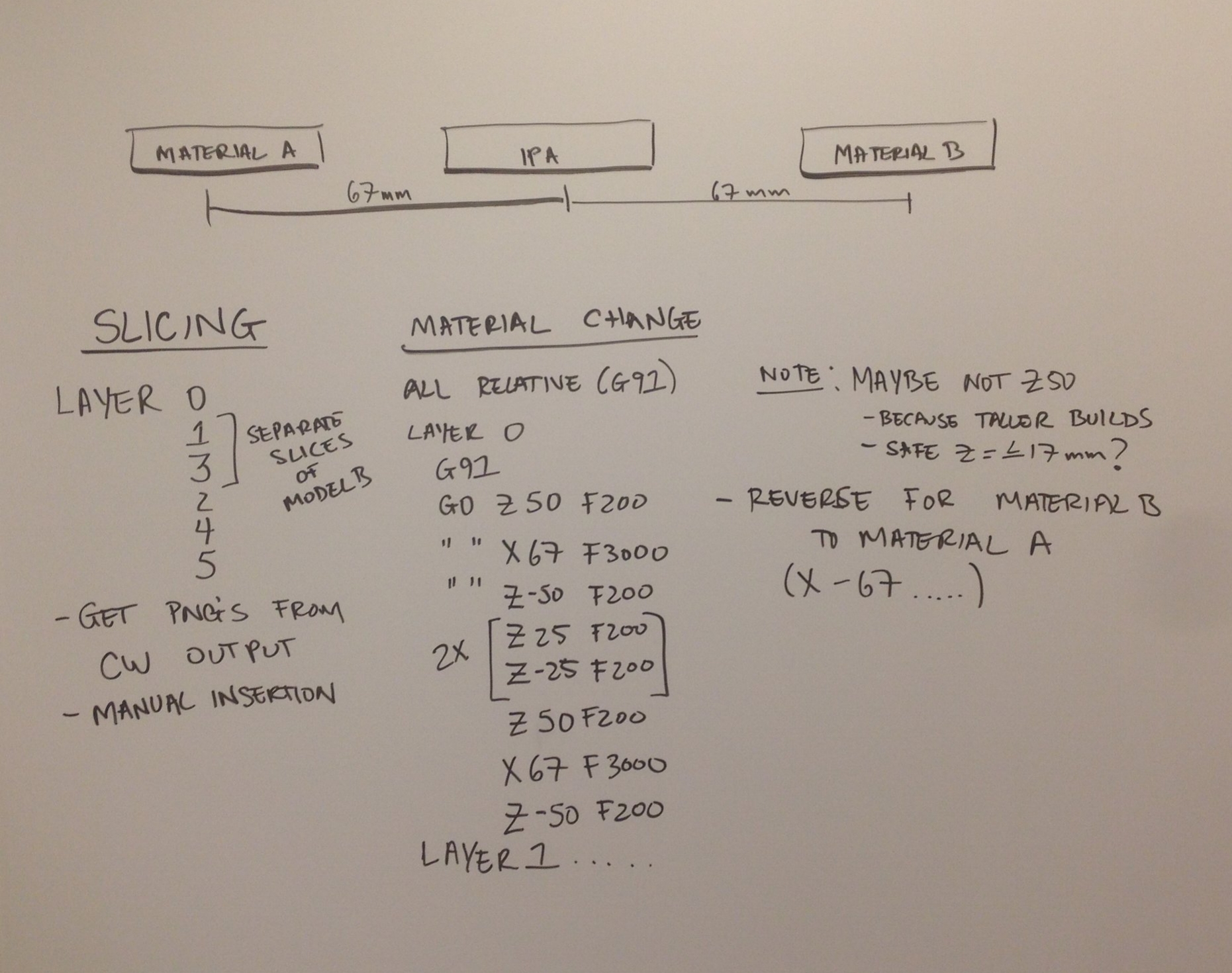

Using these constraints, the below concept was realized. Instead of a carousel, I designed a sled. The sled system would be mountable ontop of the current DLP systems. It would slide the reservoirs or in this case petri dishes in and out of the projection area. Even with more than three dishes, the foot print of the machine wouldn't increase by much. Lastly, hacking CW to support the sequence of events was fairly straightforward, though heavily manual.

Initial prototype of the MMDLP, shown with 2 materials, single wash station.

Testing

The first blob of the MMDLP! If you look, really, really closely, you can see the few layers of black.

Initially the first test was a "multicolored" print. A simple cylinder that alternated colors a number of times. Needless to say it didn't appear so promising on the first go (but when does it ever?). The thinking was if I used an uncolored resin and a dark/opaque resin, I could get a sense of how bad the potential for cross contamination was.

Future

The MMDLP is still in use at Miller Lab. The project is under active development by Bagrat Grigoryan and team. It is absolutely amazing how far they have taken this initial concept. I look forward to seeing the results of their labor in the near future. I think we will be absolutely amazed at what they have used it for in the field of tissue engineering/regenerative medicine.